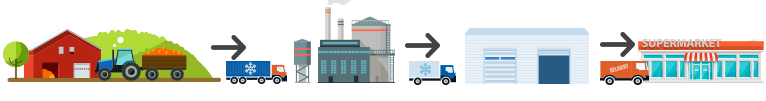

Cold Chain

The synthetic refrigerant catalyst, IceCOLD® benefits every link in the Cold Chain

- Link 1: Farm/Manufacturing Plant – IceCOLD® helps to increase the throughput of pre-coolers by reducing the time taken to cool produce to the required temperature. In addition to enhancing the processing capacity of cooling equipment, faster cooling of produce from harvest temperatures to circa 34°F can increase shelf life.

- Link 2: Cold Storage – Maintaining a consistent temperature across the Cold Chain is critical to preserving food health and quality. Improving the energy efficiency of cold storage facilities reduces operating cost. The improved energy efficiency also delivers cold air faster with lower levels of humidity.

- Link 3: Distribution – Installing IceCOLD® in refrigerated delivery trucks (Reefers) generates three key benefits:

- A significant reduction in diesel consumption resulting in cost savings.

- A significant reduction in carbon emissions resulting in environmental protection.

- A significant reduction in temperature recovery times resulting in less waste and more deliveries.

- Link 4: Food Retail – The growing consumer demand for healthier food with fewer preservatives has resulted in retailers having to install more refrigeration capacity. In the food retail environment IceCOLD® can play a major role in helping to reduce the operating costs of both comfort cooling (A/C) and refrigeration.

Reefer Example: Independent IceCOLD® Test Results

Reduce Fuel Consumption: Fuel consumption tests performed on the unit showed fuel savings of 14.30%.

Reduce Fuel Consumption: Fuel consumption tests performed on the unit showed fuel savings of 14.30%.

Reduced GHG Emissions: Tests conclude reduction in GHG emissions of 2.60 tons (tonnes) per vehicle each year based on a 9 hour run time.

Reduced GHG Emissions: Tests conclude reduction in GHG emissions of 2.60 tons (tonnes) per vehicle each year based on a 9 hour run time.

Faster Cool Down Schedules: The time to recover the interior temperature of the trailer to -10°C was reduced by 15 minutes following the installation of IceCOLD®.

Faster Cool Down Schedules: The time to recover the interior temperature of the trailer to -10°C was reduced by 15 minutes following the installation of IceCOLD®.

Reduced Compressor Run Times: The unit compressor cycled-off more frequently and throughout the test. The average duration of cycle-off times increased by 15%.

Reduced Compressor Run Times: The unit compressor cycled-off more frequently and throughout the test. The average duration of cycle-off times increased by 15%.